A1000

-

A1000 Standaard

De A1000 is de premium omvormer van YASKAWA. Het biedt een grote bedrijfszekerheid, milieuvoordelen en energiebesparingen, evenals vele andere gebruikersgerichte operationele functies die het een eersteklas keuze maken.

De A1000 is de premium omvormer van YASKAWA. Het biedt een grote bedrijfszekerheid, milieuvoordelen en energiebesparingen, evenals vele andere gebruikersgerichte operationele functies die het een eersteklas keuze maken.

- Encoder minder werking van PM-motoren met volledig koppel bij nultoerental

- Geavanceerde Auto-Tuning-functies om automatisch motorinstellingen aan te passen en continue wijzigingen tijdens het gebruik van de motor te analyseren om de hoogste machineprestaties te bereiken

- Geavanceerde energiebesparende besturingstechnologie die de efficiëntie en machineproductiviteit verbetert in combinatie met inductie en synchrone motorbediening

- Verkrijgbaar met speciale functies voor hoge snelheid spindel, positionering, kraan en takel, elektronische lijnas

Lees ook eens:

Type Premium General Purpose Inverter Range 0.55 kW – 630 kW Max. Motor Output (kW) 3~200 VAC, 0.4 – 110

3~400 VAC, 0.4 – 630Applicable Motor Induction Motor (IM)

Synchronous Motor (PM)Control V/f Control

Open Loop Vector (OLV)

Closed Loop Vector (CLV)

Open Loop Vector (OLV) for PM

Adv. Open Loop Vector (OLV) for PM

Closed Loop Vector (CLV) for PMSpeed control range V/f and V/F with PG 1:40

OLV 1:200

CLV 1:1500

CLV and OLV for PM 1:1500*3Torque Control Standard Max. Output Frequency 400 Hz

1,000 Hz*Fieldbus Interfaces RS-232C

RS-422/485 (Memobus/Modbus)

MECHATROLINK-I

MECHATROLINK-II

Ethernet/IP

EtherCAT

Modbus TCP

PROFINET

CC-Link

DeviceNet

PROFIBUS-DP

CANopenStandards CE

UL/cUL

RoHS

UL508C

EN ISO 13849-1 PLd

IEC/EN61508 SIL2Enclosure IP00, IP20, IP54, NEMA1 Functions Speed/Torque Control Switching

Energy Saving Function

Double Rating (ND/HD)

Speed Search

Slip Compensation

Torque Compensation

PID Control (with sleep function)

DriveWorksEZ (PLC SW)

Momentary Power Loss Ride-Thru

Application Parameter Presets

Preventive Maintenance Functions

RS-232C Interface

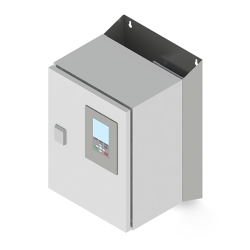

USB InterfaceA1000 IP54 Wallmount

A1000 IP54 wandmontage aandrijvingen zijn gemaakt voor decentrale installatie. Uitgerust met een ingebouwd EMC-filter, een LCD-display met duidelijke tekst in 8 talen en een optionele netschakelaar kan deze aandrijving in de kortst mogelijke tijd worden geïnstalleerd en ingesteld.

- A1000 in IP54 compact paneel

- EMC-filter ingebouwd, EN61800-3 klasse C1, IT-netfilter optioneel

- Vergrendelbare hoofdschakelaar optioneel

- Geen extra paneel, eenvoudige installatie in machines of kamers

- Ruimte voor extra componenten maakt aanpassing mogelijk

A1000 IP54 Ready

A1000 IP54 Ready is flens gemonteerd met het koellichaam aan de achterzijde, waardoor het warmteverlies buiten het paneel wordt gehouden. Het is de optimale oplossing voor kleine, klantspecifieke panelen met een hoge mate van bescherming tegen binnendringing.

- A1000 met IP54 afgedichte montageflens

- Eenvoudige installatie van één of meerdere schijven in een IP54 paneel

- Heatsink uit de achterwand brengt het grootste warmteverlies uit het paneel en maakt kleinere paneelafmetingen mogelijk

- Perfect voor kleine panelen zonder actieve koeling of ventilatie

A1000 Floorstanding

Met de A1000 vloer staande frequentieregelaar biedt YASKAWA een kastontwerp dat de installatie en inbedrijfstelling van de A1000 frequentieregelaar nu nog eenvoudiger maakt. Geconfigureerd volgens de wensen van de klant en geïnstalleerd in de schakelkast is het aandrijfsysteem direct klaar voor gebruik.

- EMC-filter (TN of IT-netwerk), hoofdschakelaar met of zonder deurgreep, remoptie, circuitremmer, zekeringen, reactoren optioneel

- Afzonderlijke luchtkanalen voor vermogensdeel en besturingsdeel zorgen voor optimale koeling en verminderen vervuiling van de elektronische onderdelen

- Standaard op de deur gemonteerd LCD-scherm met duidelijke tekst (keuze uit 13 talen)

- Optionele kastuitbreiding links of rechts voor de installatie van klantspecifieke componenten zoals voedingen, controllers of vergelijkbare apparatuur

- Beschikbaar in IP23/IP54

Voordelen:

- Eenvoudige configuratie

- Betrouwbare werking dankzij zorgvuldig geselecteerde en geproefde componenten (mechanisch, thermisch, EMC)

- Eén aanspreekpunt voor planning, aanschaf, inbedrijfstelling en service

- Minder tijd en kosten voor installatie en inbedrijfstelling