2-Assige systemen

-

ELZU

Size ELZU 30 ELZU 40 ELZU 60 ELZU 60 S ELZU 80 ELZU 80 S ELZU 100 Forces/Torques static dynamic static dynamic static dynamic static dynamic static dynamic static dynamic static dynamic Fx (N) 200 180 390 350 894 800 894 800 1,900 1,800 1,900 1,800 4,000 3,800 Fy (N) 90 60 1,200 700 3,000 2,000 4,100 3,100 3,000 2,000 4,600 3,600 8,000 6,500 Fz (N) 90 60 900 650 1,700 1,100 2,160 1,600 1,700 1,100 3,000 1,800 3,600 2,200 Mx (Nm) 10 5 25 20 67 43 88 65 90 55 170 140 300 230 My (Nm) 13 6 32 18 90 70 190 140 110 80 270 230 400 270 Mz (Nm) 14 7 35 25 120 100 230 170 150 120 300 220 750 500 No-load torqe Nm 0.2 0.6 1.2 1.2 1.8 1.8 2.6 Speed (m/s) max 2 4 5 5 6 6 8 Tensile force permanent (N) 200 390 900 900 1,900 1,900 3,600 0,2 s (N) 280 480 1,000 1,000 2,090 2,090 4,000 Geometrical moments of inertia of aluminium profile Ix mm4 4,09E+04 1,32E+05 6,79E+05 6,79E+05 18,99E+05 18,99E+05 4.44E+06 Iy mm4 4,00E+04 1,34E+05 6,97E+05 6,97E+05 18,97E+05 18,97E+05 44,8E+05 E-Modulus N/mm² 70,000 70,000 70,000 70,000 70,000 70,000 70,000

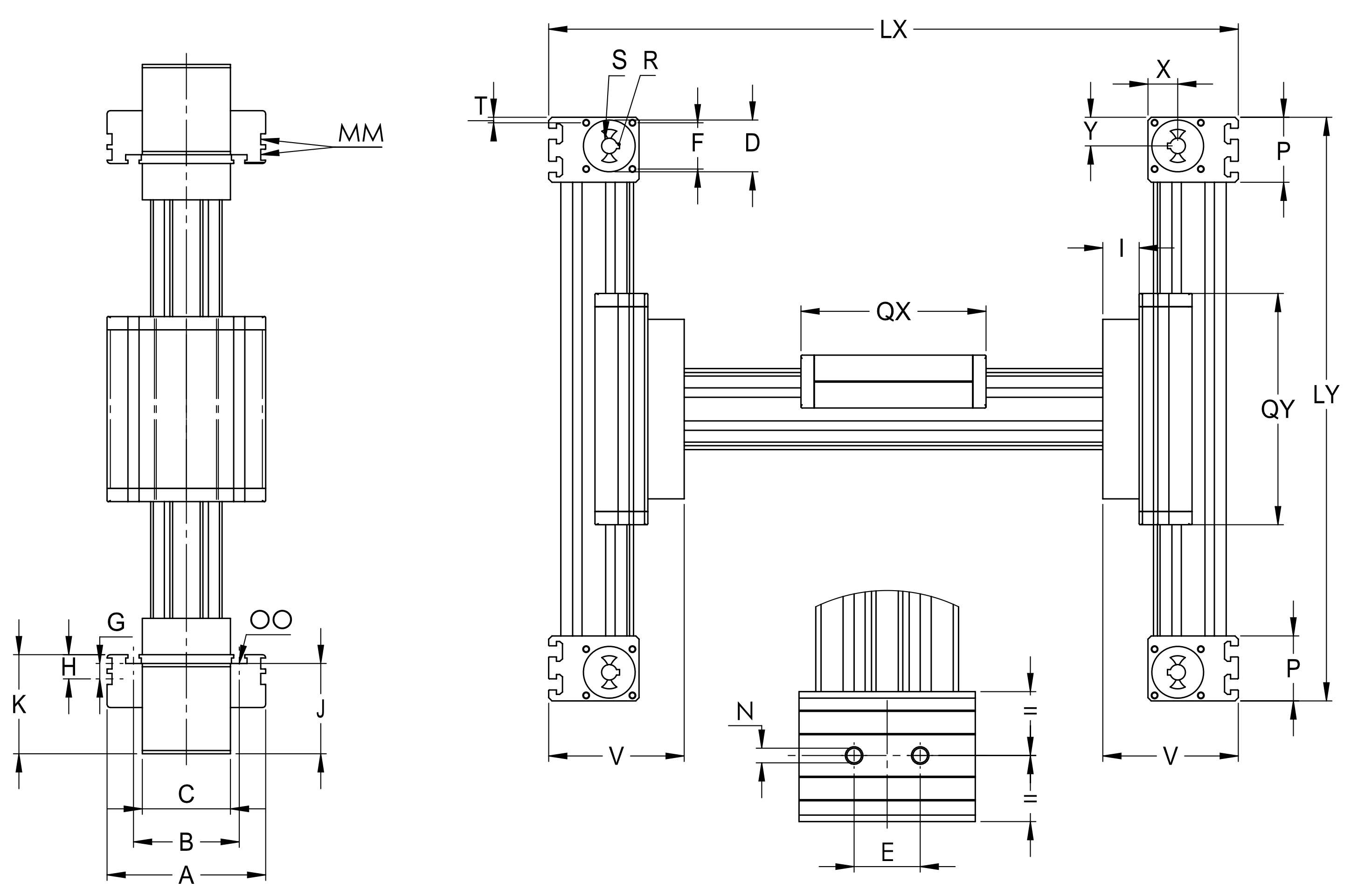

Size Basic length A B C D – 0,05 E F G H I J K MM for N for OO for P Qx Qy T V X Y Basic weight Weight per 100 mm Lx Ly ELZU 30 240 210 70 56 42 28 13 25 – – 27 44 47 – M 5 M 6 36 82 126 M 5 74 16 16 6,3 kg 0,13 kg ELZU 40 304 250 100 66 58 37 18 32 – – 26 58 64 – M 6 M 6 49 122 147 M 5 90 20.5 20.5 6,8 kg 0,24 kg ELZU 60 426 330 144 96 80 47 30 42 – – 33 82 90 – M 8 M 8 59 168 210 M 6 123 27 26 14,7 kg 0,62 kg ELZU 60S 450 330 170 108 80 47 30 42 – – 33 82 94 – M 8 M 8 59 194 210 M 6 127 27 26 17,7 kg 0,62 kg ELZU 80 535 435 170 117 100 68 40 60 10.5 30.5 44 110 121 M 6 M10 M10 90 194 244 M 8 165 39 38 31,0 kg 1,00 kg ELZU 80S 555 455 190 126 100 68 40 60 12.5 30 44 110 122 M6 M10 M 8 90 214 264 M 8 166 39 38 32,0 kg 1,00 kg ELZU 100 758 590 230 155 130 90 50 80 – 29 69 135 154 M10 M12 M10 110 300 360 M10 223 50 50 47,3 kg 1,40 kg

Size Version 1 Version 2 Belt table Shaft dimensions / Coupling claw: Qx Lx Qy Ly Qx Lx Qy Ly Belt mm/rev. Number of teeth Shaft øh6xL Key Coupling ELZU 30 94 252 126 210 94 252 138 222 3M12 75 25 6 x 15 2x2x12 7 ELZU 40 138 320 147 250 138 320 163 266 5M15 100 20 10 x 27 3x3x25 9 ELZU 60 184 442 210 330 184 442 226 346 5M25 130 26 14 x 35 5x5x28 14 ELZU 60S 214 468 210 330 214 468 230 350 ELZU 80 210 551 244 435 210 551 260 451 8M30 192 24 18 x 45 6x6x40 19 ELZU 80S 234 575 264 455 234 575 284 475 ELZU 100 316 774 360 590 316 774 376 606 8M50 256 32 22 x 45 6x6x40 24 -

ELZI

Size ELZI 30 ELZI 40 ELZI 60 Forces/torques static dynam. static dynam. static dynam. Fx (N) 390 350 894 800 1,900 1,800 Fz (N) 180 160 1,200 900 1,600 1,200 Mx (Nm) 15 9 25 20 67 43 My (Nm) 20 13 32 22 90 70 Mz (Nm) 23 18 35 25 120 100 No-load torque horizontal movement Nm 2x 0,4 2x 0,5 2x 1,1 Speed (m/s) max 2 4 5 Tensile force (please use necessarily the Mulco life-time calculation, see Chapter 4.2 permanent (N) 390 894 1,900 0,2 s (N) 480 1,000 2,090 Geometrical moments of inertia of aluminium profile lx mm4

(X-/Z-Achse)0,31E+05 / 0,41E+05 1,12E+05 / 1,32E+05 4,06E+05 / 6,79E+05 ly mm4

(X-/Z-Achse)1,70E+05 / 0,40E+05 7,20E+05 / 1,34E+05 24,3E+05 / 6,97E+05 E-Modulus N/mm² 70,000 70,000 70,000

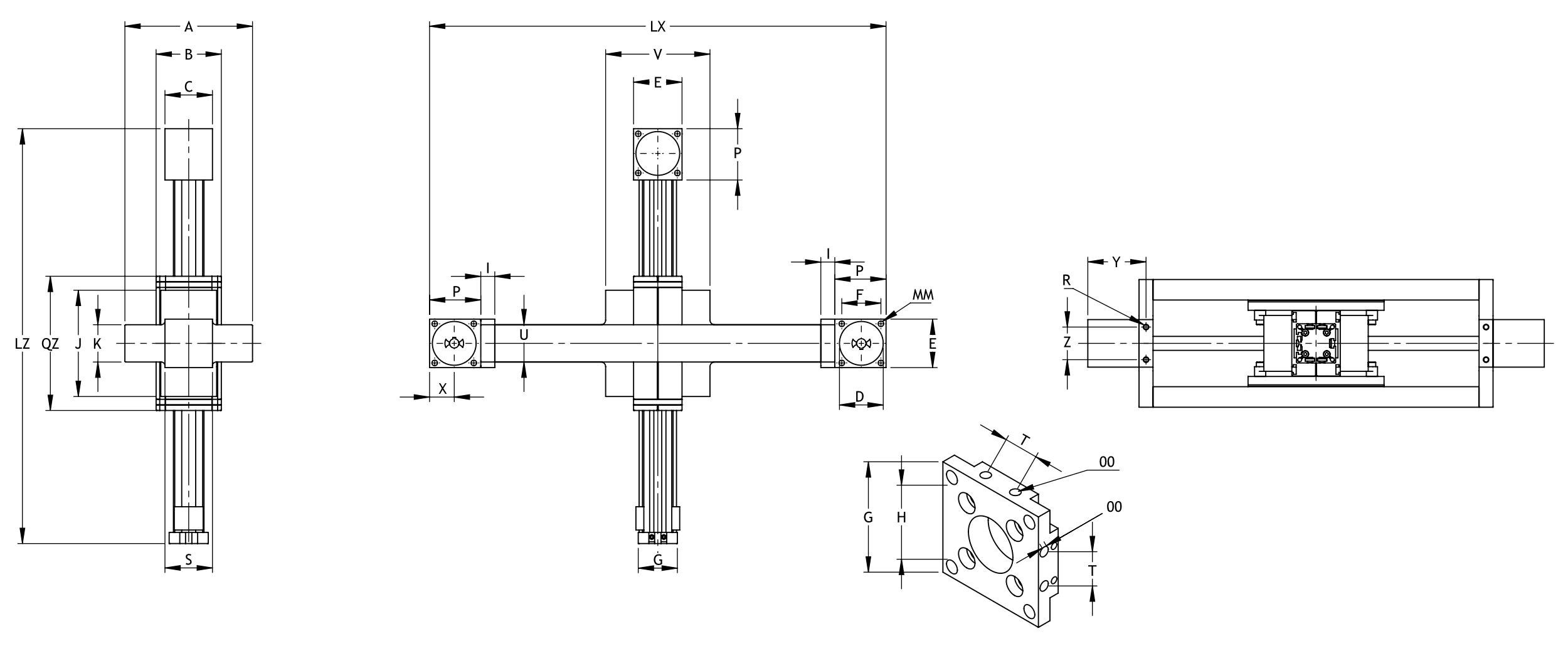

Size Basic legth A B C D – 0,05 E F G H I J K MM for N Ø OO for P Qz R for S T U V X Y Z Basic weight Weight per 100 mm X-/Z-axis Lx Lz ELZI 30 290 245 137 70 51 47 52 42 42 35 15 114 40 M6 4.2 M6 55 144 M6 60 – 40 112 26.5 62.5 35 5,20 kg 0,32/0,18 kg ELZI 40 380 290 187 100 70 55 70 55 58 47 20 125 60 M6 6.6 M6 70 165 M8 70 18 60 122 33 80 50 11,5 kg 0,68/0,3 kg ELZI 60 525 425 262 144 110 90 100 80 82 69 20 192 80 M10 8.5 M8 110 235 M10 100 30 80 198 50 120 80 33,0 kg 1,13/0,67 kg

Size X-Axie Z-Axis Belt table Shaft dimensions / Coupling claw: Profile moving mass Profile moving mass Belt mm/rev. Number of teeth Shaft øh6xL Key Coupling ELZI 30 2 x UL40 4,5 kg EL30 1,0 kg 5M15 120 24 10×27 3x3x25 9 ELZI 40 2 x UL60 7,0 kg EL40 2,4 kg 5M25 160 32 14×35 5x5x28 14 ELZI 60 2 X UL80 19,0 kg EL60 6,5 kg 8M30 224 28 22×45 6x6x35 24

Eigenschappen

2-Assige systemen kunnen worden opgebouwd worden uit componenten of lineairsystemen. Afhankelijk van de toepassing kan per bewegingsrichting 1 of meerdere systemen gekozen worden. Keuzes worden bepaald door nauwkeurigheid, stijfheid, snelheid, versnelling, belasting, omgevingsfactoren, productafmetingen, etc. Neem contact op met een productengineer van MCA om de mogelijkheden te bespreken.

Voor hoog dynamische toepassingen met een lage massatraagheid hebben twee standaard oplossingen op basis van het ‘single-belt’ principe. Hierbij worden twee assen door twee motoren aangestuurd, terwijl beide motoren niet meebewegen.

ELZU: Tandriem aangedreven systeem welke voor zowel horizontaal (XY) als verticaal (XZ) opgesteld kan worden.

ELZI: Tandriem aangedreven systeem welke hoofdzakelijk als XZ-systeem (horizontale + verticale as) toegepast kan worden